What Is a Layered Process Audit (LPA)?

A Layered Process Audit (LPA) is a systematic approach used in manufacturing to verify that standard operating procedures (SOPs) are consistently followed on the production floor. Unlike final product inspections, LPAs focus on the process itself — ensuring that each step is performed correctly, safely, and according to defined standards.

In a traditional quality audit, only the quality department checks compliance at scheduled intervals. In contrast, LPAs involve multiple layers of personnel — from team leaders to executives — conducting regular, short audits. This layered participation helps organizations maintain process discipline, detect deviations early, and reinforce accountability across all levels.

Origin and Cross-Industry Evolution of LPAs

To better understand how LPAs function today, it’s important to look at where they came from — and how they evolved across industries.

The concept of the Layered Process Audit (LPA) methodology originated in the automotive manufacturing industry, where companies such as General Motors, Ford, and Chrysler sought structured ways to verify that standardized work procedures were consistently followed across all shifts and plants. LPAs became a key element in IATF 16949 and other quality management systems, helping ensure process stability and defect prevention at scale.

Over time, however, the LPA process in manufacturing has evolved beyond the shop floor. Today, organizations in healthcare, pharmaceuticals, aviation, energy, and field services apply the same principles to verify procedural compliance, safety standards, and operational consistency.

For example:

- Healthcare: Auditing patient safety or hygiene procedures.

- Pharmaceuticals: Verifying that Good Manufacturing Practices (GMP) are followed consistently.

- Aviation & Energy: Checking critical safety and maintenance steps.

- Field Service Operations: Ensuring technicians follow approved service procedures on-site.

Because the Layered Process Audit technique is fundamentally a method for verifying process adherence, it can be applied wherever consistency, compliance, and safety are critical.

Still, manufacturing remains the largest and most mature application area, given its structured workflows, repeatable operations, and data-driven quality systems.

How Layered Process Audits Work

A Layered Process Audit (LPA) operates through a structured hierarchy of audit layers — each representing a different level of management engagement within the organization. The “layered” concept ensures that process verification isn’t limited to the quality department but becomes a shared responsibility across all organizational levels.

In most manufacturing environments, an LPA program includes three or more layers: frontline supervisors, middle managers, and senior executives. Each layer performs audits at different frequencies and with different scopes, creating a cascading system of accountability and visibility.

1. Layer 1 – Supervisors and Team Leaders

The first layer is the foundation of the LPA system. Supervisors or team leaders perform daily audits, usually at the start or end of a shift. These audits are short (10–15 minutes) and focus on critical process parameters directly related to production quality and safety.

Typical checks include:

- Whether machines are correctly set up and calibrated before operation.

- If operators follow standard work instructions step by step.

- Verification of tool condition and proper use of gauges or measurement devices.

- Inspection of safety gear usage, workstation cleanliness, and ergonomic posture.

- Confirmation that visual controls (labels, signs, color codes) are in place and visible.

Example: In an automotive plant, a Layer 1 audit might confirm torque wrench calibration or verify that operators use the correct part numbers at the assembly station.

This layer ensures immediate detection and correction of process deviations — before they affect product quality or safety.

2. Layer 2 – Middle Management

The second layer, composed of production managers or quality engineers, performs audits weekly or biweekly. These audits have a broader focus and aim to validate process discipline and consistency across shifts and departments.

Middle management LPAs often involve:

- Reviewing trends from daily audits and confirming that corrective actions have been implemented.

- Ensuring calibration and maintenance logs are properly updated.

- Checking whether new employees have received process and safety training.

- Evaluating consistency between different production lines or sites.

This layer acts as a bridge between the shop floor and upper management — turning raw audit data into actionable improvement insights.

3. Layer 3 – Senior Management or Executives

The top layer of the LPA structure consists of senior leaders such as plant managers, operations directors, or even executives from corporate quality departments. These individuals perform audits monthly or quarterly, focusing on system-level compliance and cultural reinforcement.

Their audits may include:

- Assessing whether process deviations identified in previous audits were resolved.

- Reviewing KPI dashboards for trends in defects, rework, or downtime.

- Discussing long-term corrective actions and resource needs with department heads.

- Observing audit execution firsthand to demonstrate leadership commitment.

Senior leaders’ involvement sends a strong message: quality and process discipline are strategic priorities, not just operational routines.

4. The Audit Flow and Feedback Loop

Each audit — regardless of layer — follows a closed-loop workflow:

- The auditor conducts the process check using a standardized LPA checklist.

- Nonconformities are recorded and assigned to responsible parties.

- Corrective actions are tracked until closure.

- Audit results are summarized and shared with higher layers for review.

This continuous loop of verification, correction, and communication ensures that every level stays aligned and that process issues are not just found — but fixed.

5. Key Focus Areas During an LPA

To achieve meaningful insights, LPAs typically evaluate five main areas:

- Machine setup and calibration – Verifies equipment accuracy and readiness.

- Material usage – Confirms correct parts and components are used.

- Operator performance – Ensures adherence to SOPs and safety practices.

- Documentation – Checks that logs, labels, and forms are properly completed.

- Visual management – Verifies that 5S, labeling, and visual standards are upheld.

Pro Tip: Use a digital LPA checklist that remains identical across all shifts and sites. This standardization improves data consistency, simplifies training, and reduces subjective variation between auditors.

Best Practices for Conducting Effective LPAs

A successful Layered Process Audit procedure combines structure, discipline, and continuous feedback. When properly designed, LPAs do more than catch errors — they help sustain a culture of process ownership and proactive quality.

Here are eight proven practices to make LPAs truly effective.

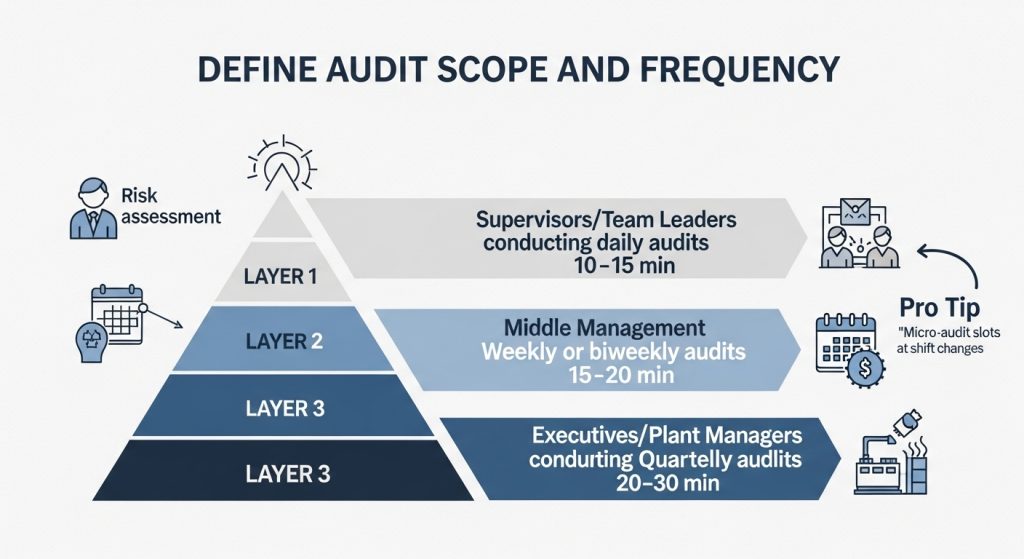

1. Define Audit Scope and Frequency

The foundation of an effective Layered Process Audit program lies in defining what to audit, how often, and at what level.

- Risk-Based Scope:

Focus on high-impact processes such as safety-critical operations, quality checkpoints, and steps that have historically produced nonconformities.

Identify the top 5 process risks per workstation and link most audit questions to those areas. - Layer-Specific Frequency:

- Layer 1 (Supervisors / Team Leaders): Daily or per shift (10–15 minutes).

- Layer 2 (Middle Management): Weekly or biweekly (15–20 minutes).

- Layer 3 (Plant Managers / Executives): Monthly or quarterly (20–30 minutes).

- Dynamic Adjustment:

Increase audit frequency temporarily in areas showing high defect rates or repeated findings.

Pro Tip: Schedule short “micro-audit slots” at shift changes — this keeps LPAs consistent without disrupting production.

2. Use Standardized Checklists

Consistency across all layers and sites is essential for reliable results.

A standardized checklist ensures that every auditor evaluates the same process criteria using the same definitions.

- Question Design:

- Use binary (Yes/No) questions backed by objective evidence.

- Keep one focus per question (e.g., “Is the torque wrench calibration label valid and visible?”).

- Avoid ambiguous or opinion-based wording.

- Structure and Format:

Include the question’s purpose, criteria for compliance, and examples of acceptable evidence. Add visuals to reduce interpretation differences. - Scoring and Severity Levels:

Define clear categories like Minor, Major, or Critical, and use a simplified risk rating to prioritize corrective actions. - Version Control:

Keep revision logs and ensure only the latest version is used.

Pro Tip: Rotate 20% of checklist questions quarterly to avoid repetitive audits and encourage real observation rather than rote compliance.

3. Provide Training for Auditors

Even the best checklist is only as effective as the person using it.

Auditor training ensures consistency, objectivity, and respectful communication on the shop floor.

- Core Training Modules:

- LPA Fundamentals

- Observation Skills

- Shadow Audit Practice

- Communication Etiquette

- Finding Documentation

- Calibration Sessions:

Once a month, have two auditors perform the same audit and compare their findings. - Mentorship System:

Pair new auditors with experienced ones for initial audits.

Pro Tip: New auditors should have their first reports co-signed by a mentor during their initial two weeks.

4. Close the Loop with Corrective Actions

An audit without follow-up is just an observation.

To achieve true improvement, every finding must result in timely corrective or preventive action.

- Structured Workflow (PDCA / 8D):

- Containment (within 24 hours)

- Root Cause (within 5 days)

- Corrective Action (within 10 days)

- Effectiveness Verification (within 30 days)

- Escalation Rules:

Set SLA targets and escalate overdue actions. - Evidence-Based Closure:

Require proof such as photos, updated SOPs, or retraining records before closure.

Pro Tip: Focus at least 70% of corrective actions on process changes — not just reminders or training.

5. Review Trends and Share Results

LPA data should fuel continuous improvement — not just fill spreadsheets.

Regular reviews make the process transparent and measurable.

- Data Analysis:

Use Pareto charts, control charts, and heat maps to visualize problem trends. - Key Metrics (KPIs):

- LPA Completion Rate

- On-Time Action Closure

- Repeat Finding Rate

- Systemic Causes

- Communication:

Share weekly summaries and monthly dashboards.

Maintain a “Lessons Learned Library” for visibility and shared learning.

Pro Tip: Keep management reports concise — a single-page summary with metrics and trends works best.

6. Governance and Audit Integrity

Accountability keeps the system credible and sustainable.

- RACI Model:

- Responsible: Auditor

- Accountable: Process Owner

- Consulted: Quality / Maintenance / Safety

- Informed: Management

- Cross-Auditing:

Avoid auditing your own area — rotate assignments. - Independent Oversight:

Have a quality coordinator review LPAs monthly for consistency.

7. Continuous Improvement of the LPA System

An effective LPA process evolves continuously.

- Refresh checklist questions each quarter based on new risks.

- Gather feedback from auditors to simplify wording.

- Convert recurring issues into preventive improvements.

- Benchmark with other facilities or industry peers.

Pro Tip: Treat your LPA system like a living process — review it annually as part of your QMS audit.

8. Templates and Tools You Can Reuse

- Audit Cadence Matrix – Layer, frequency, and duration per process.

- Checklist Header – Includes process, equipment ID, revision, and auditor name.

- Finding Report Template – Captures nonconformity, evidence, and closure proof.

- Monthly Dashboard – Summarizes completion rate and top findings.

Pro Tip: Use digital tools or dashboards to automate these templates and ensure traceability.

Digitizing the LPA Process

Modern Layered Process Audit software enables manufacturers to replace paper-based systems with a digital platform — improving accuracy, visibility, and efficiency.

Integration with systems like ISO 9001, IATF 16949, or ERP tools allows automatic data syncing and faster decision-making.

Key Advantages:

- Automated scheduling

- Mobile-friendly checklists (online/offline)

- Photo and signature capture

- Instant reporting and analytics

- Unified dashboards

By digitizing, manufacturers not only enhance compliance but also strengthen continuous improvement and collaboration across all teams.

Final Thoughts: From Insight to Action with FieldPie

As industries move toward data-driven quality systems, digital LPAs have become an integral part of operational excellence. Layered Process Audits remain a cornerstone of manufacturing process control — enabling consistency, accountability, and measurable progress.

✅ Ready to simplify your quality audits?

FieldPie helps manufacturers digitize and manage Layered Process Audits with mobile checklists, automated scheduling, and instant reporting.

Book a demo today and see how FieldPie transforms process control into continuous improvement.